Problems are not. A s area of primary tension reinforcement A n area of tension reinforcement 1146 STEP BY STEP PROCEDURE The followings are the step by step procedure used in the flexural design for corbel bracket as follows.

Angle Bracket Combined Loading Youtube

Figure 1 90 angle bracket with a rib - nailing pattern.

. 11 shows the design result of the double L-bracket with two stress constraints and together with a pure stiffness maximization design result for comparison. The shelf will be 30 inches deep trying it with a 025 inch thick steel bracket that is 1 inch wide supported at one end the wall and with a load of 1 pound at the far end of the shelf. Also the calculation is better done around the non-centroidal x0y0 axes followed by application of the the Parallel Axes Theorem.

Wl3 3EI 1303 3290000000001302083 0238344797. Moment of inertia of a rectangle. CD is fixed at 90deg to AB 130mm from the top.

Force-displacement curves for nails axially loaded. Guide to Design Criteria for Bolted and Riveted Joints Second Edition Geoffrey L. One horizontal element CD 375mm long.

I have a cantilever bracket fixed at one end free at the other. Bracket which can be less or more than the width of the compressor. A constant downward load W30kg is applied to the end of CD l375mm.

SL L240 15 inforsnowloadand. When youre done customizing your bracket have it analyzed and quoted for manufacturing right in the software. Bolts and base of the compressor may have shape which will help us bolting the compressor to the plate.

However a more straightforward calculation can be achieved by the combination ACBC-C. Hi I am a Computer Engineer who may be in a little over my head in producing my own brackets for a shelving project I am working on. AMERICAN INSTITUTE OF STEEL CONSTRUCTION Inc.

Download eMachineShops free CAD to start with a bracket design from our extensive library of parts and shapes. One vertical element AB 330mm long with a fixing at either end to a wall. Design of a Rigid Column Bracket Welded Determine the size of the components required to connect the bracket to the column shown in figure below using Grade S355 steel.

The final area may be considered as the additive combination of ABC. Custom Bracket Design Software. Design custom brackets easily.

Here is a picture of the bracket that I designed and I am thinking about making it with 14 inch 6061 aluminum with the following properties. Analysis of weld group The total length of weld Lw 2dw bw 2400 200 1200 mm. The steel angle bracket is to be supported at both ends by means of other two sets of angle brackets vertical positioned which are to be attached to I-Beams.

Lets say that I would like to utilize a L 5 x 3 12 x 38 bracket to support a vertical load laying evenly on top of it. Ah 05As An 1111 where. Department of Energys Office of Scientific and Technical Information.

Comparison of characteristic load-bearing capacities. One East Wacker Drive Suite 3100 Chicago IL 60601. Direction of forces relative to the supporting beam and the purlin The characteristic load-carrying capacities Fk are intended to be used for the calculation of the design.

This leads to shape of side closed L bracket Dimension of the bracket. Each problem is intended to serve as a quick reference for the procedures on a particular topic. 498 DESIGN EXAMPLES INTRODUCTION This chapter contains example problems in a format similar to what a designer might use when performing hand calculations.

Physical and Mechanical Properties Ultimate Tensile Strength psi 45000 Yield Strength psi 40000 Brinell. The forces shown are applied to one gusset plate at ultimate load. Cantilever Bracket Calculations.

D40 mm l 90 mm laterally loaded. The limits of horizontal closed stirrup reinforcement at corbel design is. Wh312 1 0253 12 0001302083.

Thursday July 2 2015. Assuming centre of pressure 25 mm below top of cleat point A horizontal shear force on bolt due to moment due to eccentricity e 150 502 20050212522002 129 kN V2exri ri2 vertical shear force per bolt 1506 250 kN resultant shear 12922502 2813 kN. D25 mm l40 mm.

Up to 24 cash back Example 5. Design Project Calculation Sheet Checked by VK Date 3 Flange Splice Portion of load carried by each flange 05440-1028 1686 kN For M22 HSFG bolts 4 Nos in single shear Shear force bolt 16864 4215 kN Slip resistancebolt 11 u 045 u 177 8762 kN Bearing resistancebolt 22 u 9 u 650 u 10-3 1287 kN.

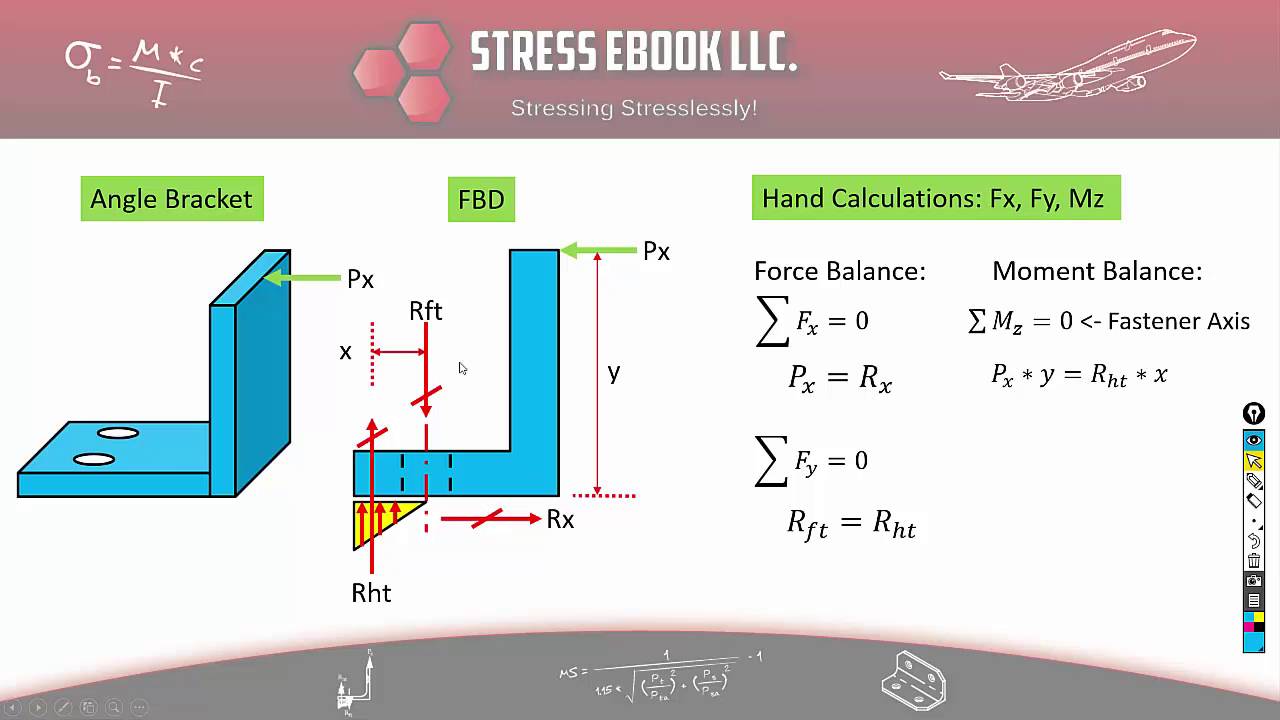

Angle Bracket Horizontal Load Heel Toe Youtube

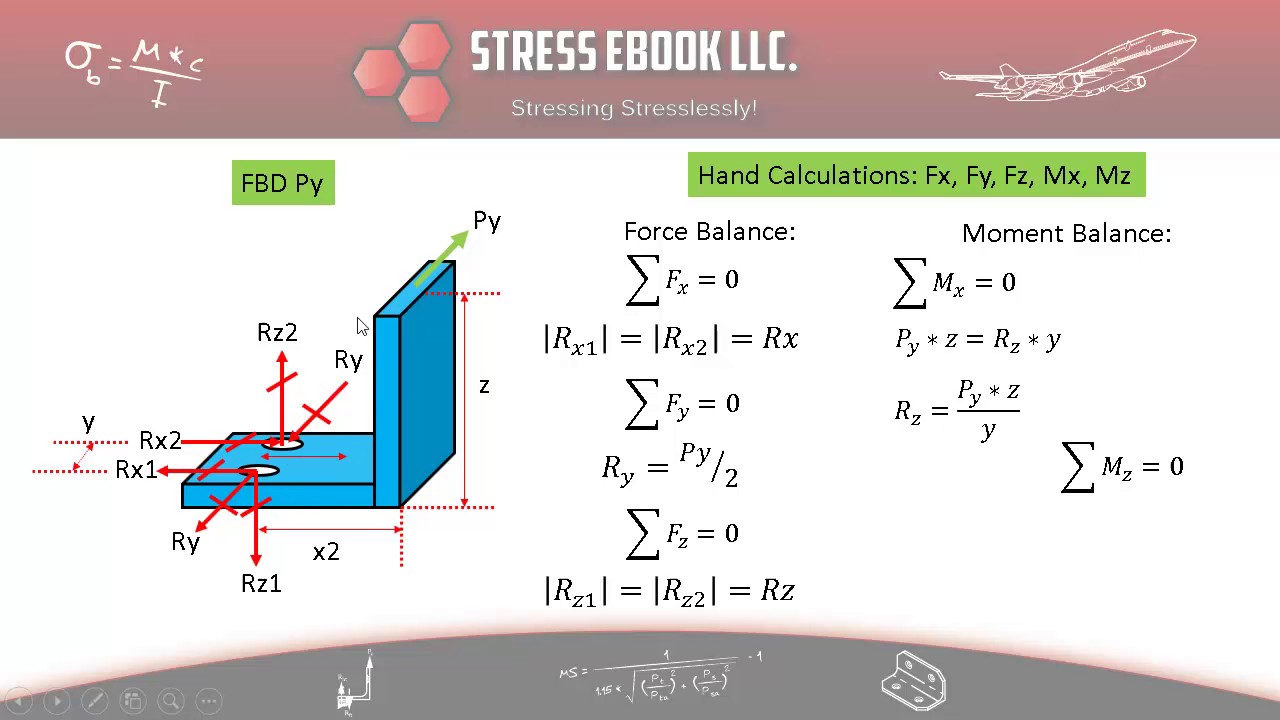

Angle Bracket Sizing And Stress Analysis Stress Ebook Llc

Mechanical Engineering Ch 11 Friction 8 Of 47 Bracket On A Pipe Youtube

Mechanical Design Tutorials On Basic Calculations Bright Hub Engineering

An L Shaped 1020 Steel Support Bracket Must Support A Chegg Com

Mechanical Design Tutorials On Basic Calculations Bright Hub Engineering

Angle Bracket Combined Loading Youtube

Pull Away Load On L Bracket Top Leg Hand Calculation Finite Element Analysis Fea Engineering Eng Tips

0 comments

Post a Comment